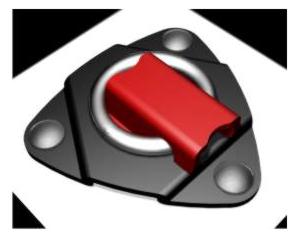

Ultimax Recessed Rotating Ring Anchor

Model TA-6

High-quality Tie-Down Anchors designed to complement BLACK+GRAY's distinctive line of motorcycle, roadracing and transport products. Unique in the industry for their strength, materials, flexibility and range of applications.

- Unique design achieves rotation without rivets, pivots, springs or pins that can fail.

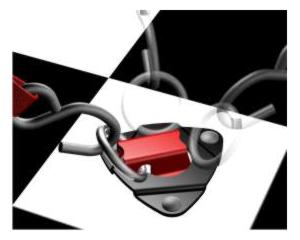

- Allows 360° horizontal rotation and 180° vertical ring and tie-down strap rotation.

- Ring is easily accessible/lifted from recessed receptacle for ease of use

- Ring feature provides additional angular direction for tie-down straps

- Easily installed into floor surface: receptacle requires hex cut-out x .75" deep

- Reinforcement plate is included!

- Patent No. US 7,686,551 B2 & US 8,414,237 B2

- Made in the USA

WARNING: Do not use any Ultimax Tie-Down Anchors for overhead lifting.

Product Details

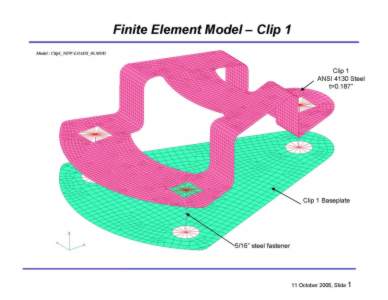

- 8 gauge, (.164") very high quality, heat treated 4130 steel

- Weight: 16 oz / 0.45 kg

- high quality polyester powder-coat finish

- 304 Stainless Steel Welded Ring: 5/16" x 1 1/2 " (.312" x 1.5";)

- 14 gauge (.074") powder cpoated or zinc plated (for corrosion resistance) reinforcement plate included

- 5/16" grade 5 zinc plated mounting hardware included

- Designed, Engineered, Tested and Manufactured in the USA

Ultimax Tie-Down Anchors are tested and load-rated at angles of 90°, 45° and 30°

WLL (working load limit) factor of safety = 3

The working load limit of a component or tie-down assembly is 1/3 of the product's rated capacity or breaking strength (breaking strength is the load a component or assembly will withstand before failure). Never exceed the Working Load Limits (WLL) published for each Ultimax Tie-Down under any condition.

Six Ultimax Tie-Down Anchor models provide options for vertical or horizontal mounting, in open or corner applications. They range from a simple one-piece anchor to a unique recessed anchor that rotates 360º without axles or pins. All are manufactured of 4130 steel alloy with powdercoat finishes. Selected models include 304 stainless steel rings.

Unlike off-the shelf, off-shore-manufactured products offered by competitors, Ultimax Tie-Down Anchors are designed, engineered, tested and manufactured in the USA.

Ultimax Tie-Down Anchors are tested and load-rated at angles of 90°, 45° and 30°.

WARNING: Do not use any Ultimax Tie-Down Anchors for overhead lifting.

BLACK+GRAY's reputation as an innovator in motorcycle, roadracing and transport products is based on 30 years experience in design, engineering and motorcycle riding, racing and hauling. Ultimax Tie-Down Anchors fill the void in high-quality, application-specific hardware for motorcycle and other transport needs.

Look carefully at existing tie-down hardware and we think you'll agree that serious motorcyclists and road racers deserve better. Competitors' web sites feature the same six or seven off-shore manufactured,cheaply plated or unfinished products. They provide little or no information on the materials used in manufacturing. They cite load ratings but provide little or no verifiable information on what those ratings mean. They say that products are tested but don't say how and by what standards. They use test ratings for 90º vertical loads as benchmarks, when standard practice is to tie down motorcycles at 30º to 45º.

At BLACK+GRAY we took a different approach. Our intention was to create top quality hardware with design distinction and special function for specific conditions and applications. We started out by looking at what our customers need and where existing products fail to fill the bill. We conducted regulatory research to define product standards (and discovered that although there are government regulations for many aspects of cargo transport, there are none that specifically address the anchors to which cargo is tied. Consumer Beware.) We did extensive materials research and testing. We explored scores of design solutions and had final prototypes evaluated using FEA (Finite Element Analysis) by consulting engineers who count NASA among their clients. We tested production-ready Ultimax Tie-Down Anchors in our own facility using stringent, verifiable standards and procedures. And we contracted with US manufacturers to supply high quality parts.

What you get is what you see… and at BLACK+GRAY what you see matters. Our goal is to design innovative products that are as elegant in the way they look as the motorcycles they complement. That goes for everything we do – from wheel chocks to apparel to hardware to the way we package what we sell.

What you get is also more than what you see. At BLACK+GRAY we are serious about function, performance and quality. We design and manufacture products for people who won’t settle for "good enough." Ultimax Tie-Down Anchors are in a class by themselves. Unique in appearance and attention to detail, they are also unique in the industry for their strength, materials, flexibility and range of application.

You can get cheaper but you can’t get better.

All Ultimax Tie-Down Anchors are made from high carbon steel 4130 alloy then heat treated. High and Medium carbon steels allow the heat treatment to penetrate, producing a much stronger material than low carbon steel, which is merely surface hardened. Ultimax models that employ rings feature 304 stainless steel rings manufactured by a US marine supplier. Grade 5 carriage bolts and locking nuts are supplied. Parts are powder coated to provide a durable, good-looking finish.

Ultimax Tie-Down Anchors were tested by BLACK+GRAY using certified load scales and a custom built testing jig driven by a hydraulic cylinder ram. Tests were conducted at 90°, 45° and 30°. (The 90° standard was developed by the lifting industry which manufactures cranes and other vertical equipment. Pull data at 90° are much less critical for motorcycle tie-down than data at the most frequently used 45° and 30° positions.) BLACK+GRAY tested all models at all three angles to enable customers to choose the appropriate solution for their vehicle, cargo, use conditions and trailer design and construction.